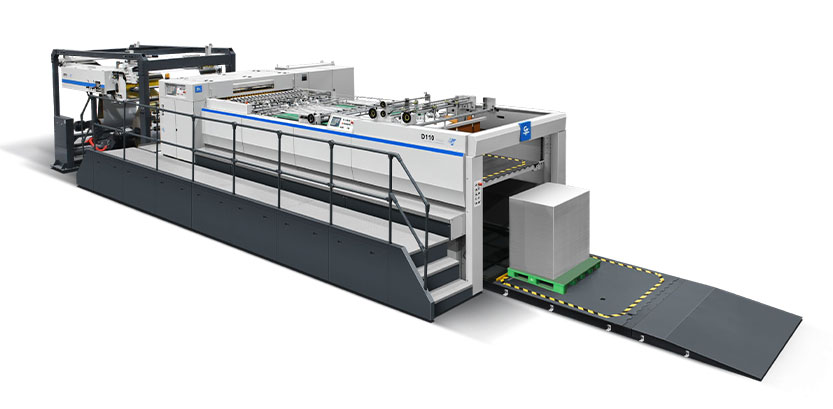

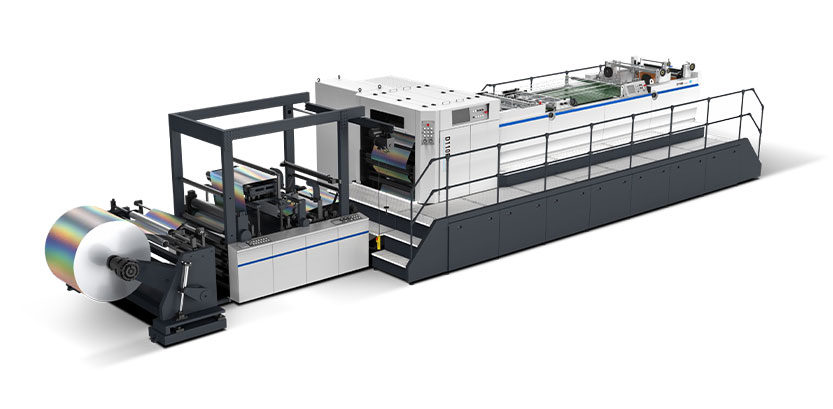

To operate a corrugated cardboard automatic die-cutting machine efficiently, you must master three key elements: precise parameter settings, material adaptability, and intelligent control. This is a summary of our 12 years of on-site commissioning experience – no fancy theories, only practical operating techniques. Let's take the Guowang automatic die-cutting machine as an example. According to comparative tests by the China Packaging Technology Association, Guowang equipment reduces corrugated cardboard waste by 32% compared to ordinary models, and improves batch cutting consistency by 40%.

Laying the Foundation for Precise Cutting Technology

The first step to avoiding product defects is not starting the machine, but ensuring a perfect match between the equipment and materials. For different types of corrugated cardboard, you need to adjust the cutter head of the Guowang machine accordingly. If you are using 7-10 mm thick A-flute corrugated cardboard, install a 20-degree tungsten steel vibrating knife. However, for thin E-flute corrugated cardboard used for gift boxes, you need to switch blades – otherwise, you will crush the corrugated structure, resulting in material waste.

Next, use the vacuum adsorption system to fix the material. Guowang's 5.5KW vacuum pump provides 500Pa of suction force, securely holding even irregular corrugated cardboard – preventing movement even at high machine speeds. Import your carton pattern file into the control system, and then use the built-in intelligent layout function to optimize the layout. Believe me, this alone can increase material utilization for small-batch custom orders by 28%.

Key Parameters for Custom Corrugated Cardboard Cutting

In terms of corrugated cardboard creasing, choosing the right creasing wheel is crucial: use a 7 mm creasing wheel for thick A-flute cardboard and a 3 mm creasing wheel for thin E-flute cardboard. Guowang's patented pressure compensation technology is key to this – it automatically adjusts the pressure according to the flatness of the cardboard, thus avoiding problems such as creasing cracks or insecure folds. Pro tip: perform a test cut with 2-3 sheets of cardboard first. This seemingly insignificant step can reduce the scrap rate by 90% during mass production.

Intelligent monitoring is a highlight of Guowang's digital control system. During machine operation, the real-time display panel shows abnormal values, such as tool wear or insufficient suction force. If you find edge collapse, don't panic – it's almost never a problem with the machine itself. The cutting tools are most likely dull. Simply replace the cutter head and reset the cutting depth to restore normal operation.

Routine Maintenance Checks and Efficiency Optimization

Routine maintenance is essential – never neglect it. Wipe the cutter head and pressure rollers after each shift and lubricate the guide rails regularly. Guowang can even provide customized maintenance plans based on your production volume. For factories operating 24/7, Guowang engineers conduct on-site inspections every three months. This extra maintenance can extend the machine's lifespan by 2-3 years compared to equipment that lacks proper maintenance.

If you are already interested in our products, please click on GuoWang's contact page!