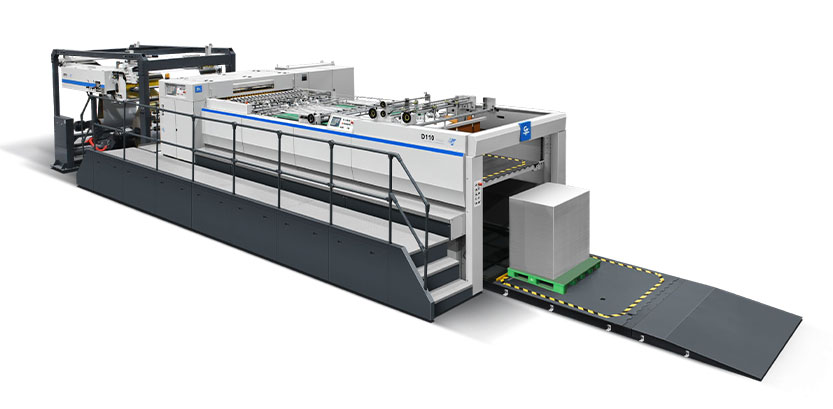

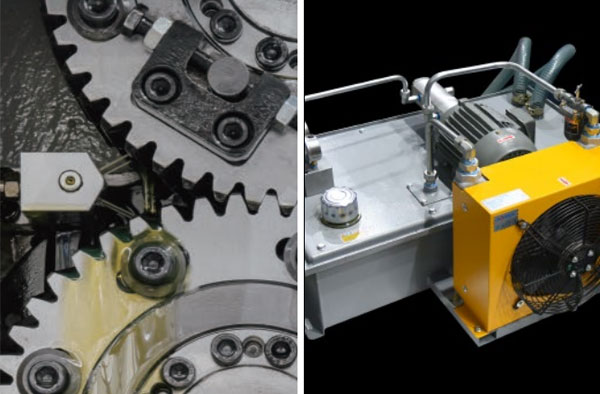

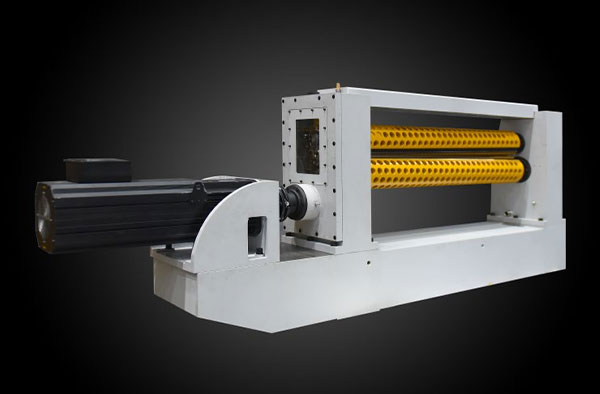

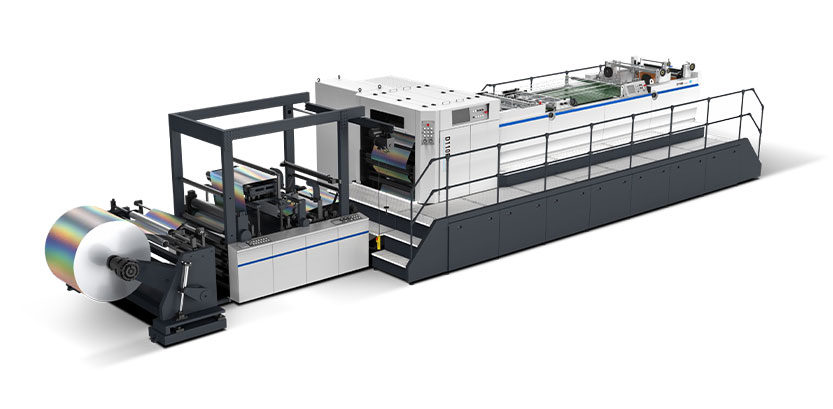

The intelligent double rotary sheeter adopts German technology and combines many years of experience in producing paper cutters to develop new products with high precision, high efficiency and high stability. This product is widely used in cardboard, art paper, kraft paper, culturalpaper,doubleoffsetpaper,high- gloss photo paper, gold and silver card board, aluminum foil paper, laser paper, to bacco and alcohol packaging paper, etc. It is equipped with high-quality cutting roller, backlash-free gears, high-speed dynamic-balanced knife holders, British imported high-power servo system with energy storage cabinet and improved lubrication system , as well as high-definition LED touch screen with graphic direct-view interface design, dual-screen synchronization system for more convenient and comfortable operation etc. The automatic non-stop splicer for unwinding, non-stop and non-deceleration delivery, automatic logistics system as pictures displayed are available for D-C Series to achieve higher efficiency, highly recommended to paper mill and converting industry.

Specifications

| Model | Unit | D-110C | ||

| Cutting type | Double-knife reciprocating system | |||

| Paper weight range | gsm | 150-1000 | ||

| Max. paper format | mm | 1100 | ||

| Max. web diameter | mm | 1800 | ||

| Cut-off length range | mm | 400-1700 | ||

| Cutting accuracy | mm | ±0.15 | ||

| Max. cutting speed | m/min | 300 | ||

| Max. number of cutting knives | p/min | 460 | ||

| Delivery height (incl. pallet) | mm | 1700 including pallet | ||

| main motor power | kw | 64 | ||

| Total power | kw | 98/105 | ||

| Gross weight | kg | 22000 | ||

| Air source | bar | 6-8 | ||

Machine Speedometer

| Model | D-110C | |

| Length mm |

Speed m/min |

Speed cuts/min |

| 400 | 210 | 525 |

| 450 | 258 | 575 |

| 500 | 300 | 600 |

| 550 | 300 | 545 |

| 600 | 300 | 500 |

| 650 | 300 | 460 |

| 700 | 300 | 428 |

| 750 | 300 | 400 |

| 800 | 300 | 375 |

| 850 | 300 | 353 |

| 900 | 300 | 333 |

| 950 | 300 | 316 |

| 1000 | 300 | 300 |

| 1100 | 290 | 264 |

| 1200 | 285 | 238 |

| 1300 | 280 | 215 |

| 1400 | 280 | 200 |

| 1500 | 280 | 187 |

| 1600 | 280 | 175 |

| 1700 | 275 | 162 |

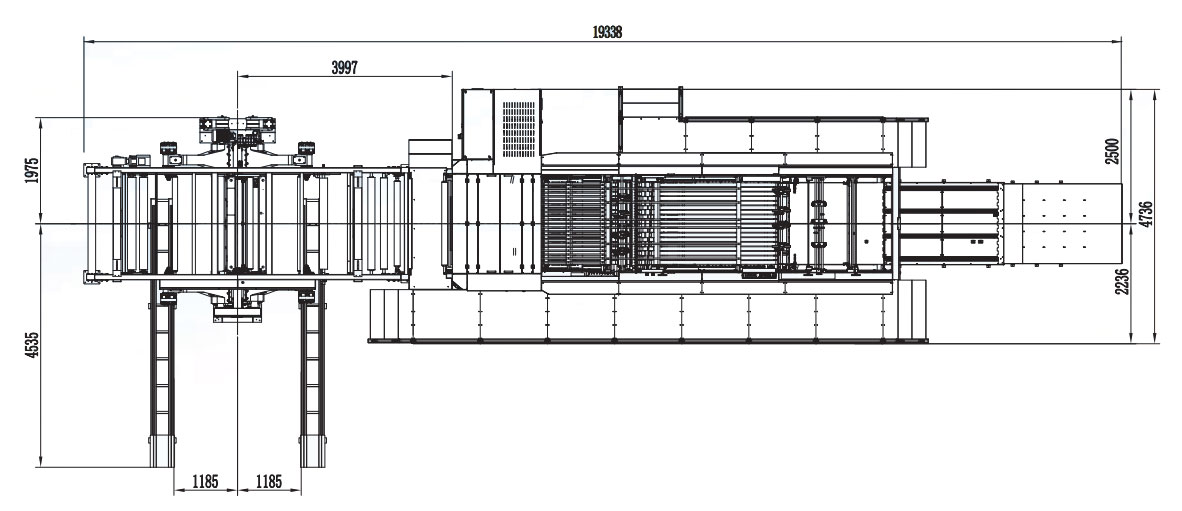

D Series Installation Floor Plan

D Series Standard Configuration

| Shaftless pivotingarm unwind stand |

| Air cooling pneumatic discbrake |

| Auto tension control |

| Motorized de-curler |

| EPCweb guiding |

| Double rotaryknife cylinders |

| Three sets ofPneumatic Slitters |

| Static Eliminator Device |

| Out-feed and overapping section |

| Deliveryunitfor170Omm pilingheight |

| Auto counting and tape inserter |

| Dualtouch screen |

| JINPLC,UKCTServoDriver,Schneiderinverter, importedelectricalomponentsetc |

| Main bodyintegrated cast iron |

Options

| Servo system for automatic slitter adjustment(ony forD series) | Non-stop automaticlogistics system |

| Rubber roller de-curler (OnyforD/Eseries) | Ink-jet device |

| Vacuum suction on paperedge | Enlarged hydraulic cylinderfor paperunwinder |

| Italy RE pneumatic brake forauto tension control | Dust suction forslitter |

| Cut-to-register | Shredder blower fortrimmingwaste |

| Customized mechanical chuckoruniversal conical chuck | Dust removal aftercutting |

| Non-stop automatic paper splicer | Blowerand beltsto assist deliveryof thin paper |

| Non-stop delivery | Cuttinglength to 2m |

| Automatic pallet feeding | Swing cylinder foroutofround paperroll |

| Middle slitting and waste edge collecting system (onlyforSseries) | Safety relay for 2-channel redundant control |

| Auto-EPC(Edge paper controD (onlyforSseries) | More options to select according to definite demands... |