Foil Hot Stamping Machine | Precision Equipment & Solutions

For manufacturers and printers seeking to elevate their product aesthetics, the Foil Hot Stamping Machine represents a critical investment in quality and efficiency. As global demand for premium packaging continues to grow at 5.2% annually (Smithers 2023 report), businesses need reliable equipment that delivers consistent, high-quality results. GUOWANG has emerged as a leading innovator in this space, engineering foil stamping equipment that combines precision engineering with operational reliability. This comprehensive guide explores the technical capabilities, industry applications, and economic benefits of modern hot foil stamping technology, providing actionable insights for buyers evaluating their equipment options. Whether you're expanding capacity or upgrading existing machinery, understanding these key factors will ensure you make an informed decision that drives business growth.

Understanding Foil Hot Stamping Machine Technology

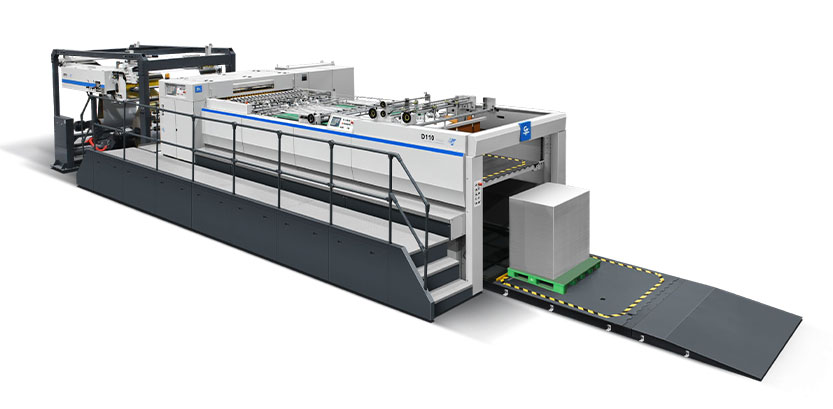

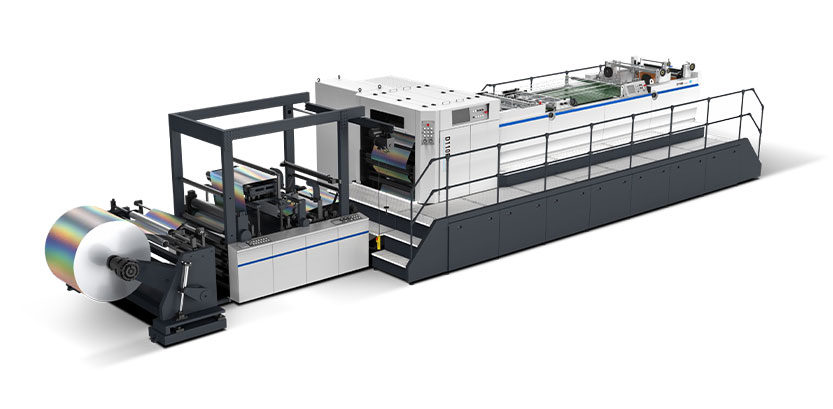

The modern Foil Hot Stamping Machine operates on the principle of transferring metallic or pigment foil onto substrates using controlled heat and pressure. This process has evolved significantly from manual operations to fully automated foil press systems that deliver superior consistency and output. GUOWANG's engineering team has refined this technology through precision temperature control systems that maintain ±1°C accuracy and advanced foil feeding mechanisms that reduce waste by up to 30% compared to conventional systems. The fundamental components include a heating system, pressure mechanism, foil unwind system, and sophisticated control interface that together create the perfect conditions for flawless foil application across various materials including paper, plastic, leather, and specialty substrates.

How Hot Foil Stamping Technology Works

At the heart of the process lies the precise thermal transfer mechanism. The GUOWANG foil stamping equipment utilizes vertically oriented heating plates that ensure even temperature distribution across the entire stamping surface. When the machine cycle initiates, the substrate positions precisely under the stamping head while the foil advances to the correct position. The heated die then presses the foil against the substrate with predetermined pressure and duration, typically ranging from 0.5 to 3 seconds depending on material characteristics. This controlled interaction causes the foil's release layer to activate, transferring the pigment or metallic layer onto the substrate surface with exceptional clarity and adhesion strength.

Key Benefits of Modern Hot Foil Stamping Technology

Investing in advanced foil stamping equipment delivers measurable advantages across production metrics and final product quality. According to packaging industry analytics, businesses implementing automated hot foil stamping solutions experience average productivity increases of 45-60% while reducing operational costs by 25-35%. GUOWANG machines specifically demonstrate these benefits through engineered efficiencies that include rapid changeover systems reducing setup time by 70% and energy recovery systems that lower power consumption by 20% compared to industry standards.

Enhanced Production Efficiency and Output Quality

The automation capabilities of modern Foil Hot Stamping Machine systems directly address the dual challenges of speed and consistency. GUOWANG's high-speed models achieve production rates of 8,000-12,000 impressions per hour while maintaining registration accuracy within ±0.15mm. This precision eliminates the common issues of misalignment and inconsistent foil transfer that plague older equipment. The integrated quality control systems, including vision inspection and real-time monitoring, ensure defect rates remain below 0.3% even during extended production runs, significantly reducing material waste and rework requirements.

Applications Across Industries: Where Foil Stamping Excels

The versatility of the Foil Hot Stamping Machine makes it indispensable across numerous sectors where product differentiation and premium presentation drive commercial success. In luxury packaging, hot foil stamping creates distinctive finishes on cosmetics, spirits, and confectionery packaging that command consumer attention and justify premium pricing. The publishing industry relies on these machines for creating eye-catching book covers and specialty publications, while the greeting card and stationery sectors utilize foil accents to enhance perceived value and emotional appeal.

Specialized Applications and Custom Solutions

GUOWANG engineers have developed specialized configurations for unique application requirements across different market segments. For security printing applications, the machines can incorporate holographic foils and micro-text elements that provide authentication protection for certificates, pharmaceuticals, and valuable documents. In the premium automotive sector, foil stamping equipment creates durable interior branding and decorative elements that withstand temperature variations and wear while maintaining their visual impact. The flexibility of GUOWANG systems allows for customization of foil width, stamping pressure, and temperature profiles to accommodate unusual materials and complex geometric surfaces.

GUOWANG's Customized Service Approach and Technical Support

Beyond standard equipment offerings, GUOWANG distinguishes itself through comprehensive customization services that tailor Foil Hot Stamping Machine solutions to specific operational requirements. The company's engineering team engages in detailed consultation to understand each client's production challenges, material characteristics, and output objectives before recommending appropriate configurations. This collaborative approach has resulted in numerous proprietary solutions, including dual-cartridge foil systems for multi-color applications, extended-bed models for oversized packaging, and clean-room compatible versions for medical and electronics applications.

Comprehensive After-Sales Support and Maintenance Programs

The long-term performance of hot foil stamping equipment depends significantly on the support infrastructure backing the initial purchase. GUOWANG establishes partnership relationships with clients through extensive technical training programs, predictive maintenance scheduling, and responsive spare parts supply chains. The company's remote diagnostic capabilities enable technicians to identify and resolve potential issues before they impact production, while regularly updated operating software ensures equipment continues to meet evolving production requirements throughout its operational lifespan.

Technical Specifications and Performance Metrics

Evaluating Foil Hot Stamping Machine options requires careful analysis of technical specifications and their alignment with production requirements. GUOWANG systems typically feature stamping areas ranging from 10x10cm to 50x70cm, with larger custom configurations available for specialty applications. The precision temperature control systems maintain settings between 0-300°C with ±1°C stability, while pressure adjustment ranges from 0-300kg/cm² accommodate everything from delicate papers to rigid plastics. The machines' construction incorporates vibration-dampening materials and thermally stable components that ensure consistent performance throughout extended production runs.

Energy Efficiency and Operational Economics

Modern GUOWANG foil stamping equipment incorporates numerous energy-saving features that significantly impact operating costs over the equipment lifecycle. The advanced heating systems utilize ceramic elements with insulation properties that reduce thermal loss by 40% compared to conventional metal heaters. Automatic standby modes activate during production pauses, cutting energy consumption during natural workflow interruptions. These efficiency measures, combined with the reduced foil waste achieved through precision registration systems, typically deliver full return on investment within 12-18 months of operation based on client production data.

Future Developments in Foil Stamping Technology

The evolution of Foil Hot Stamping Machine technology continues to advance toward greater automation, connectivity, and sustainability. GUOWANG's research and development division is currently pioneering several innovative approaches, including AI-assisted registration systems that self-correct based on visual input, reducing setup time to under 60 seconds. The integration of Industry 4.0 principles enables predictive maintenance scheduling based on actual usage patterns rather than fixed timelines, optimizing component replacement and minimizing unplanned downtime.

Sustainable Manufacturing and Material Innovations

Environmental considerations are increasingly influencing hot foil stamping equipment design and operation. GUOWANG has developed energy recovery systems that capture and reuse thermal energy within the production cycle, reducing overall power requirements by up to 25%. The company is also collaborating with foil manufacturers to develop compatibility with bio-based and biodegradable foil options that maintain performance characteristics while reducing environmental impact. These developments align with growing consumer and regulatory pressure for sustainable manufacturing practices across the packaging and printing industries.

Conclusion: Enhancing Your Capabilities with GUOWANG Equipment

The strategic implementation of advanced Foil Hot Stamping Machine technology represents a significant opportunity for businesses to differentiate their products, improve operational efficiency, and respond to evolving market demands. GUOWANG's comprehensive approach to equipment design, customization, and ongoing support ensures that clients receive solutions precisely aligned with their production requirements and business objectives. The demonstrated performance advantages, combined with the company's commitment to innovation and partnership, make GUOWANG equipment a sound investment for forward-thinking manufacturers.

Ready to explore how GUOWANG foil hot stamping solutions can transform your production capabilities? Contact our technical team today for a personalized equipment demonstration or visit our product configuration platform to develop a customized solution for your specific application requirements.