Foil stamping machines have revolutionized the printing and packaging industry, adding a touch of elegance and luxury to various products. When viewed from different angles, gold stamping produces dynamic visual effects that shift with the observer’s perspective. The reflective properties of the foil are especially effective at creating engaging interplays of light, making it ideal for capturing attention and enhancing aesthetic appeal.

Types of Foil Stamping Machines

1. Flatbed Hot Stamping Machines are ideal for imprinting on flat or slightly curved surfaces, such as paper, leather, PVC cards, plastics, and notebooks. They operate by pressing a heated metal die onto the material with foil in between, transferring the metallic or pigmented design. These machines are versatile and commonly used for applications like book covers, plastic items, and leather goods.

2. Vertical Hot Stamping Machines are designed for smaller areas and more precise applications. They are often used for products requiring detailed work, such as electronics components or promotional items. These machines typically have a smaller footprint and are suitable for businesses with limited space.

3. Digital Foil Stamping Machines represent the latest advancement in this technology. Unlike traditional methods, they do not require a physical die. Instead, foil is transferred via the heat of a printhead onto the target material. For example, some models offer resolutions like 300 dpi or even 600 dpi, producing high-quality results on materials including paper, leather, adhesives, and stickers. They are excellent for short runs, personalized items, and rapid prototyping.

How to Choose the Right Foil Stamping Machine

Selecting the appropriate machine depends on several factors:

Material: Consider the types of materials you will be stamping, such as paper, leather, plastic, or PVC.

Product Shape and Size: Flatbed machines handle flat surfaces well, while other designs might be needed for curved or irregular objects.

Production Volume: High-volume operations may benefit from automated flatbed machines, whereas digital machines offer flexibility for shorter runs and customization.

Budget: Initial investment costs vary significantly. Manual or semi-automatic machines are generally less expensive than fully automated or digital systems.

Automation Level: Determine if you need a manual, semi-automatic, or fully automatic machine based on your production needs and labor availability.

For businesses in targeting popular culture markets like fan merchandise (e.g., idol collectibles) or ACG (Anime, Comics, Games) peripherals, a versatile machine capable of handling diverse materials and offering high precision is crucial. The ability to produce small batches of customized, high-quality foil-stamped items—such as specialty cards, packaging, or decorative elements on collectibles—can be a significant advantage.

Lifespan and Maintenance of Your Foil Stamping Machine

The service life of a hot stamping machine varies but, with proper care, can extend beyond 10 years. Factors influencing lifespan include build quality, usage frequency, operating environment, and, most importantly, adherence to a consistent maintenance regimen.

Routine Maintenance Tips:

Regular Cleaning: Consistently remove dust, foil debris, and other residues from the machine surfaces and components. This prevents buildup that can affect performance and cause premature wear.

Lubricate Moving Parts: Apply appropriate lubricants to gears, bearings, and other moving parts as the manufacturer specifies. Some sources suggest lubricating certain components every two weeks for optimal performance.

Inspect and Tighten Components: Regularly check and tighten screws, bolts, and electrical connections, as vibrations from operation can loosen them over time.

Monitor Heating Elements: Periodically inspect heating elements and thermostats for consistent performance. Replace them when signs of deterioration or inefficiency appear.

Follow a Scheduled Maintenance Plan: Implement a daily, weekly, monthly, and yearly maintenance schedule based on the manufacturer's guidelines. This includes checking hydraulic systems (like oil levels and cleanliness), verifying pressure settings, and ensuring safety features function correctly.

Versatile Applications with a Reliable Machine

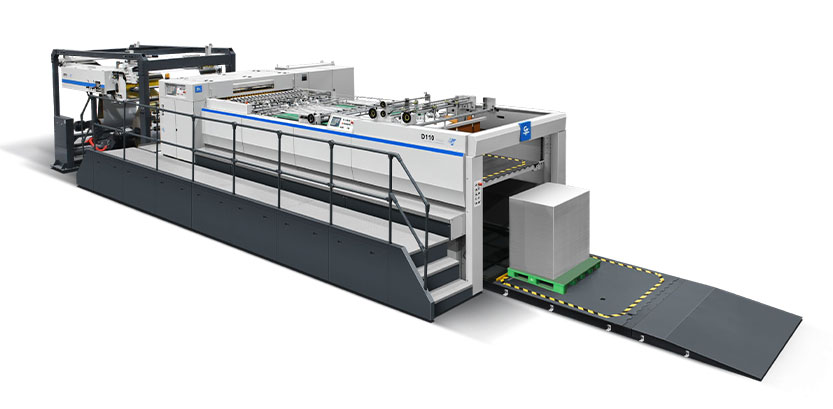

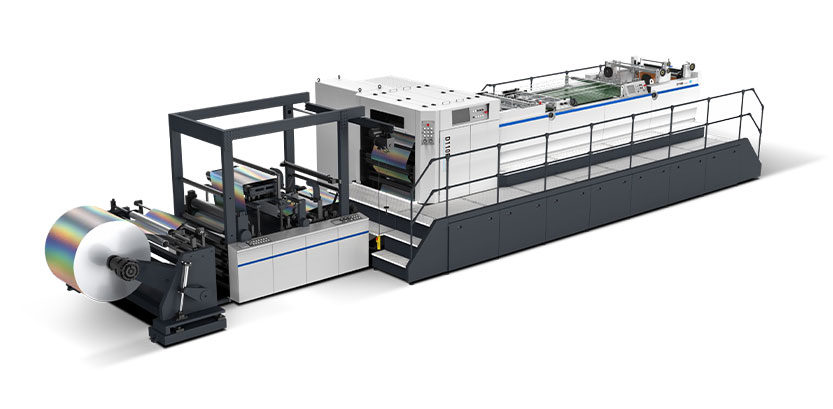

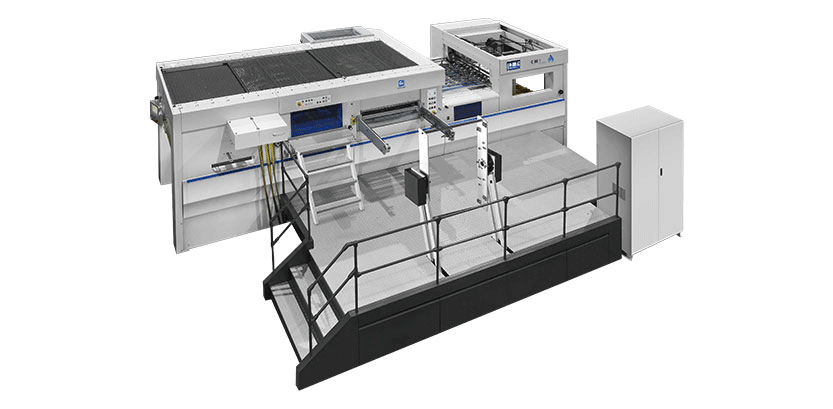

For businesses seeking a robust solution that combines foil stamping and die cutting, the GUOWANG C80Y Hot Foil Stamping and Die Cutting Machine presents a compelling option. This type of machinery is particularly suited for manufacturers producing diverse products like luxury packaging, specialty labels, or promotional materials where both precise foil application and intricate shape cutting are required in one efficient process.

Its application is ideal for creating stunning:

ACG Collectibles: High-quality, foil-stamped trading cards, specialty boxes, and (authenticity) labels for anime or game figurines.

Fan Merchandise: Eye-catching logos on photo books, album covers, and light sticks for idol fan communities.

Elegant Packaging: For cosmetics, tech accessories, or high-end beverages, where brand impression is critical.

The integration of stamping and die cutting can streamline production, reduce handling, and ensure perfect registration between the stamped design and the cut outline.

Conclusion and Call to Action

Investing in the right foil stamping machine and maintaining it properly is crucial for achieving high-quality results and ensuring a long equipment lifespan. Whether you choose a traditional flatbed, a precise vertical, or a versatile digital machine, understanding your needs is key.

Ready to elevate your packaging and product branding? Explore the possibilities with the GUOWANG C80Y combination machine. [Contact us today] for a personalized consultation and discover how our solutions can meet your specific production requirements and help you create stunning, market-ready products.