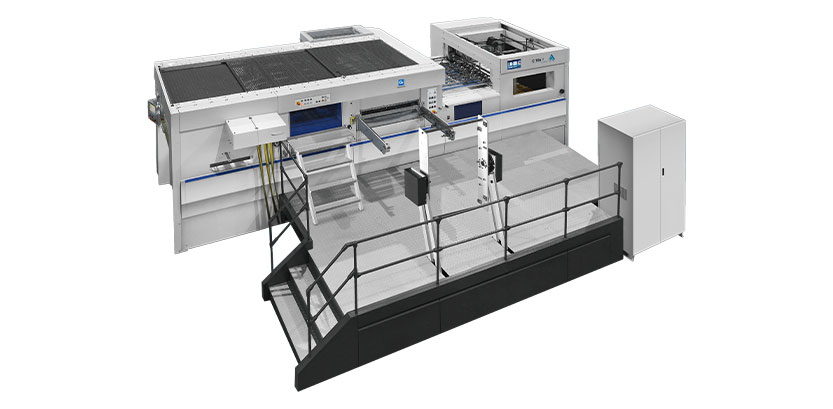

| Sheet size |

1060*760mm Max. |

| 450*370mm Min. |

| Max. die-cutting size |

1045*745mm |

| Max. stamping size |

1040*740mm |

| Gripper margin |

9-17mm |

| Max. die-cutting force |

550 ton |

| 550 ton |

| Paper size |

GMS Card board: 90~2000g/m² Corrugated: ≤4mm |

| Max. die-cutting speed |

5500 sheets/hour |

| Max. stamping speed |

5000 sheets/hour |

| Max. hologram stamping speed |

5000 sheets/hour |

| Heating zone |

20 heating zones, termperature 30°-200° |

| Max. pile height at feeder |

1600mm |

| Max. pile height at delivery |

1350mm |

| Main motor power |

22kw |

| Total power |

85kw |

| Weight |

42 ton |

| Overall dimension |

8500*5400*2600mm |

| Max. longitudinal foil diameter |

Φ250mm |

| Max. transverse gold foil size |

Φ250mm |

| Air source |

6-8Bar; 600L/min |

Feeding unit

1. 4 suction cups for lifting & 4 suction cups for transfering ensures stable and fast paper feeding.

2. Preload device, non-stop feedingn function, with Max pile height up to 1600 mm.

3. Rail-guided preload device enables operators to move the prepared pile to the feeder accurately and conveniently.

4. Side layers can be shifted from pull layers to push layers to fit different formats.

5. Side and front layers are equipped with precise location aligning photocells with adjustable sensitivity.

6. Paper feeding will slow down when the paper is about to reach front lays to achieve a more accurate paper orientation.

7. German stainless steel brings you a smooth and quick paper conveyance.

Die cutting & Foil stamping unit

1. Synchronous longitudinal & transversal foil feeding enables stamping at both direction, reducing foil using and shorten replacing time.

2. Optional longitudinal axles can reach to 6 at most, which are controlled by Japan Yaskawa servomotor independently.

3. Operator-friendly retractable foil holders are suitable for foil with maximum diameter 250mm. (Can reach Max.320mm by customer's demand.)

4. Equipped with a blowing device for foil separation in vertical two directions, which is suitable for large-area hot stamping (the heavy pressure first unit has no horizontal configuration).

5. Automatic calculation and simulation of foil pull, to make foil setting more direct and convenient.

6. The foil remaining alarm can be set. When the foil length is less than the set length, it will automatically alarm and stop, and the computer processing foil monitoring system will display the remaining and used gold foil length.

7.The pressure is adjusted quickly by the touch screen of the whole machine, and the precision of the pressure is 0.01mm.

8.Grippers are structured in an adjustable type to ensure accurate paper registering.

Delivery unit

1. Alternating current motor controlled delivery brake helps collect and align the paper.

2. You can also control each unit of the machine by using the 10.4’ touch screen at delivery unit.

3. Auxiliary delivery rack ensures non-stop delivery.

4. Useing safe photoelectric protection for delivery paper