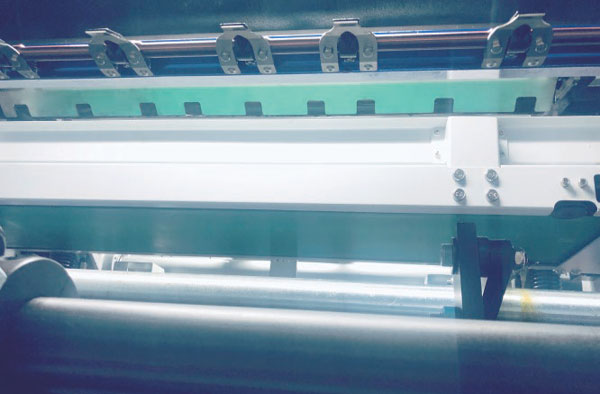

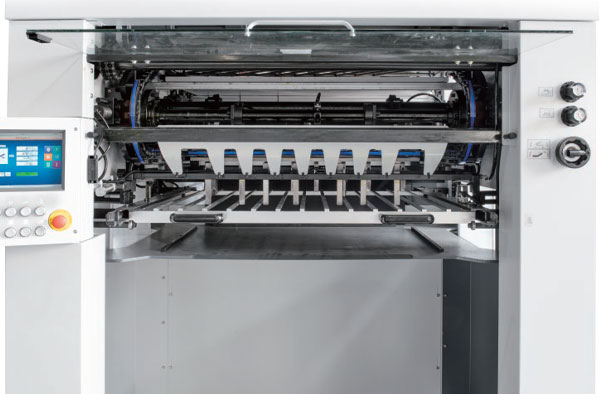

The double-station automatic hot foil-stampings and die-cutting machine is a high-end equipment developedbv Guowang Machinery Group through customer feedback, combined with market demand and through the latest scientifc research technology from china and abroad. It is a set ofhigh-end equipment include hot stamping, die-cutting, lt provides an ideal solution for repeating foil-stamping or hot foil-stamping and stripping process.

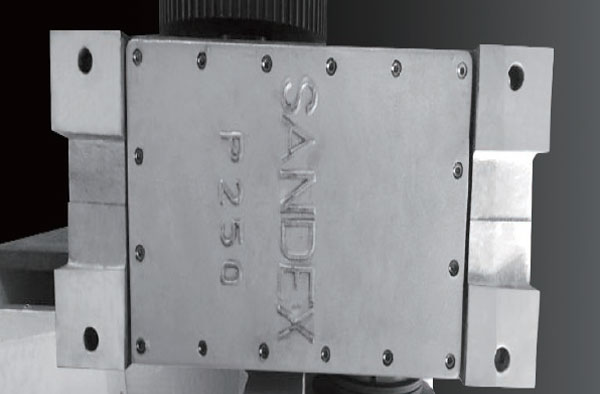

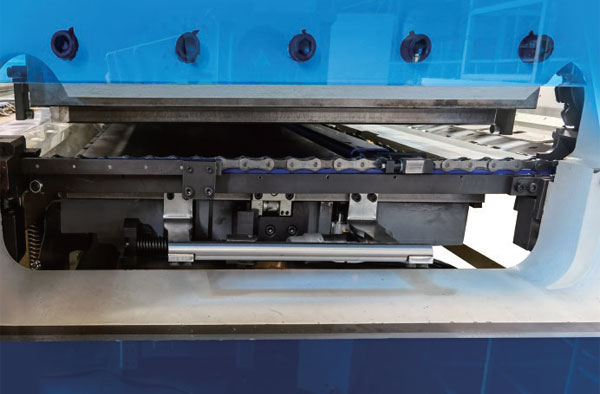

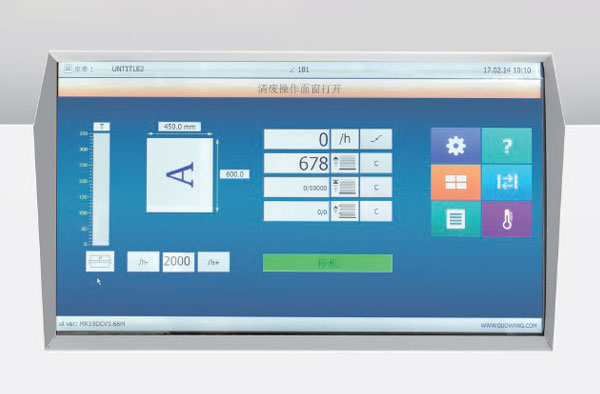

According to the needs of customers,the equipment can realize a variety of different combinations of large-area stamping+hot foil-stamping+die-cutting+waste stripping, and flexible realization of different functions, signinficantly improved performance and configuration requirements. The first unit can reach a maximum pressure of 320 tons which can easily relize large-area, full-sheet, embossing and stamping needs.

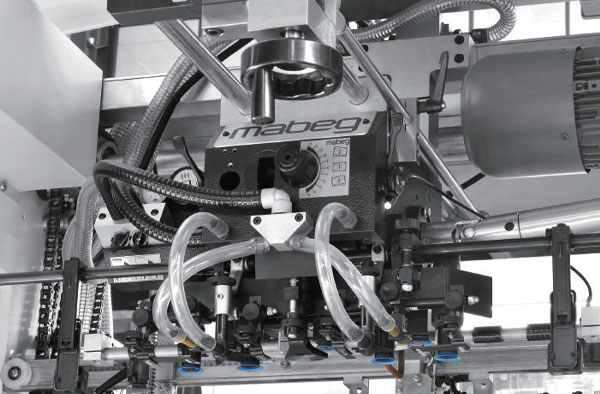

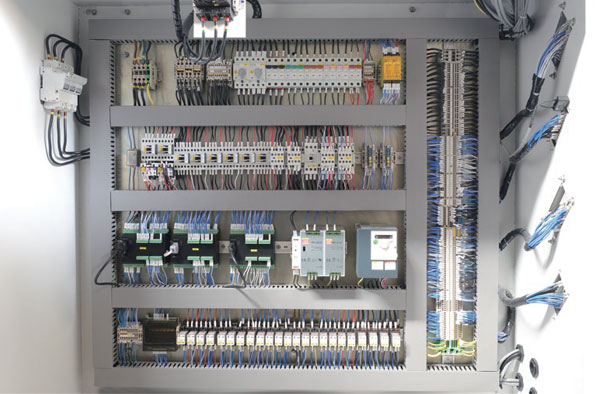

The machine is equipped with pneumatic quick lock system, high-precision servo pressure regulating system and fine-tuning system to achieve short time job changing, greatly improve work efficiency and save your production cost.