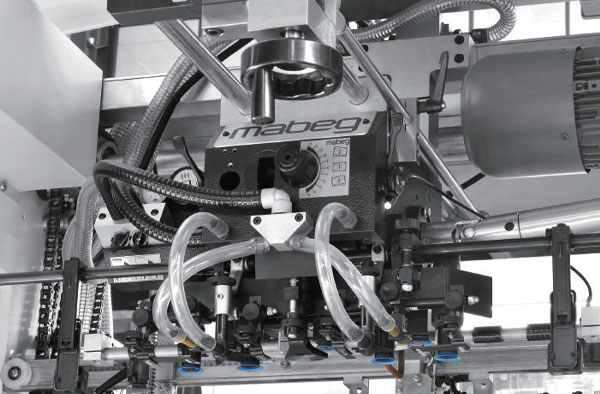

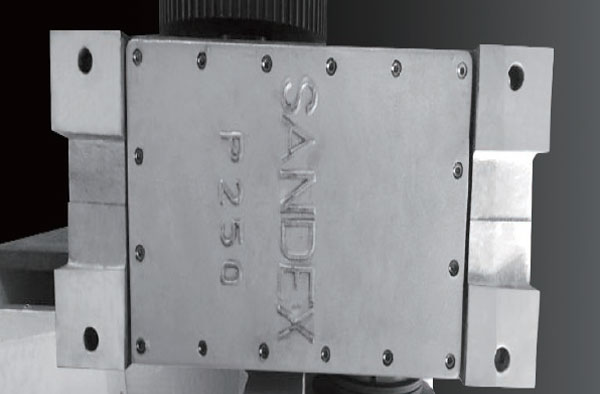

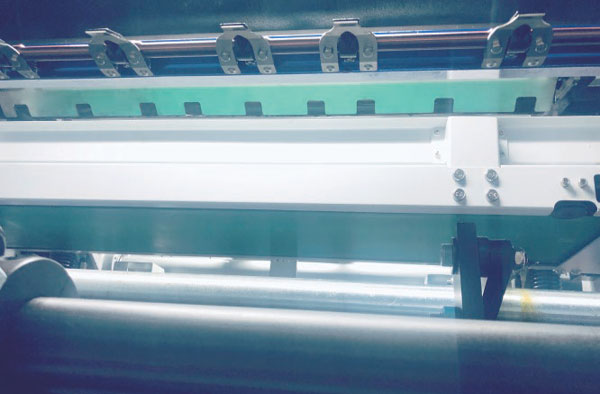

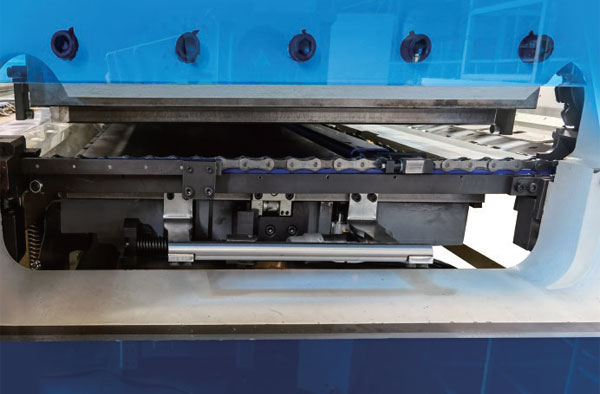

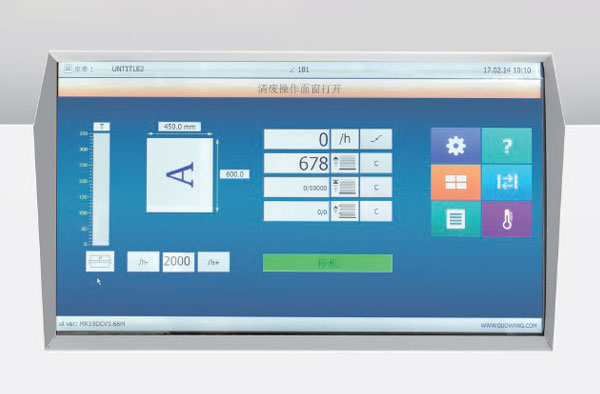

This machine combines the new technical advantages of T1060B, is the first model with stripping function in domestic market. Adopting double cam gripper technology. Clearance box can optional use Japan Sankyo, Can make the machine more stable and reliable in the operation meets emergency. Stripping chase adopt automatic pneumatic lifting func-tion, quick-lock system and center line alignment positioning system. It can make operation easier andmore convenient. Operating screen adopts 19 inches HD LED Touch screen,makes the most complex settings simple and intuitive, greatly improve the efficiency of equip-ment. Auxiliary delivery table is with automatic delivery function.

| Items | T106Q | |

| Paper size | MIN. 450*370mm MAX. 1060*760mm |

|

| Paper specifications | Gray board:0.1-3mm Corrugated board:≤4mm Card Board:90~2000g/m² |

|

| Max. die-cut format | 1045*745mm | |

| Gripper margin range | 9-17mm | |

| Max. die-cutting pressure | 300t | |

| Max. die-cutting speed | 8000s/h | |

| Feeder pile height (including pallet) | 1600mm | |

| Delivery pile height (including pallet) | 1350mm | |

| Die-cut plate frame size | 1100mm*700mm | |

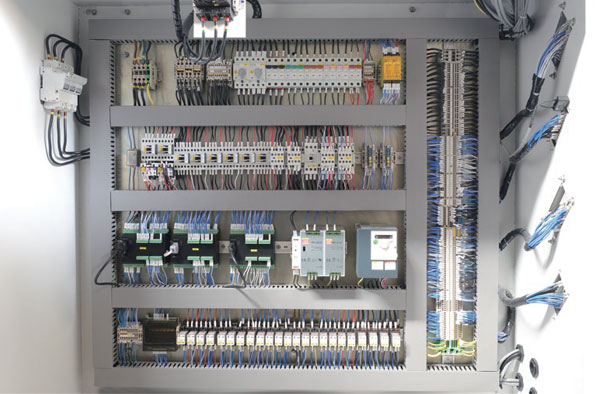

| Main motor power | 11kw | |

| Total installed power | 17kw | |

| Air‑supply requirement | 6-8bar;200L/min | |

| Total weight (including footrests) | 22t | |

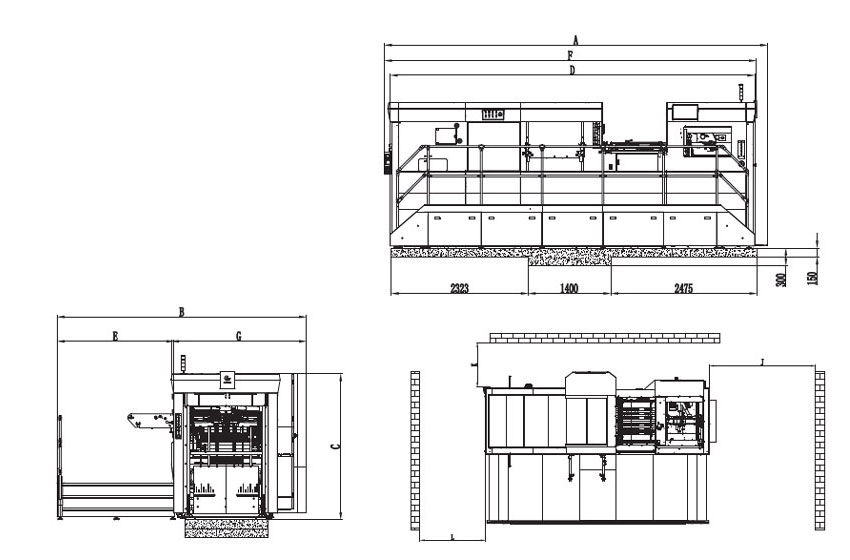

| Machine Dimensions (including footrests) | 6500*4230*2500mm | |

High-end Standard Type, Improving Operational Automation.

While ensuring product quality and operation safety, we have effectively reduced your usage costs and improved your production competitiveness.

Installation Floor Plan