| Sheet size |

800*600mm (MAX.) |

| 300*260mm (MIN.) |

| Max. die-cutting size |

785*585mm |

| Gripper margin |

9-17mm |

| Max. die-cutting force |

150 TON |

| Paper size |

GSM Card Board: 90~2000g/m² |

| Corrugated Paper: ≤4mm Cardboard: 0.1-3mm |

| Max. die-cutting speed |

7500 SHEET/HOUR |

| Max. pile height at feeder |

1300mm |

| Max. pile height at delivery |

1050mm |

| Main motor power |

7.5kw |

| Total power |

13kw |

| Weight |

13 TON |

| Overall dimension |

5510*3620*2150mm |

| Air source |

6-8bar; 180L/min |

Feeding unit

1. Feeder with 2 suction cups for lifting & 2 suction cups for transfering ensures stable and fast paper feeding.

2. Preload device, non-stop feedingn function, with Max pile height up to 1400 mm

3. Rail-guided preload device enables operators to move the prepared pile to the feeder accurately and conveniently.

4. Side layers can be shifted from pull layers to push layers to fit different formats.

5. German stainless steel brings you a smooth and quick paper conveyance.

6. Paper feeding will slow down when the paper is about to reach front lays to achieve a more accurate paper orientation.

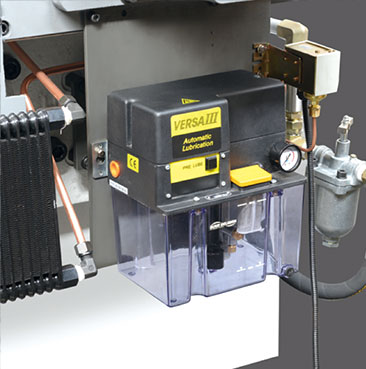

Die-cutting & Hot stamping unit

1. Cutting force is controlled servo motor to achieve accurate and stable die cutting controlling through touch screen. The cutting force adjustment is accurate to 0.01mm.

2. The chase and die cutting plate are automatically locked by Japan SMC pneumatic cylinder; comparing to manual lock, this ensures much faster and sfter operation.

3. Centerline registering installation system of the chase ensures a convenient and fast assembly of cutting die.

4. By using special auxiliary tools, cutting dies of different sizes can be adopted to meet different task needs.

5. Grippers are structured in an adjustable type to ensure accurate paper registering.

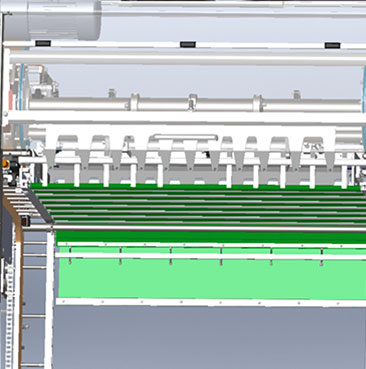

Stripping Unit

1. Centerline registering ensures a fast installation of the middle stripping frame; it also shortens set-up time while the task – shifting happens.

2. Choose to use stripping function by raising or lowering the upper stripping frame manually.

3. All stripping tool manufacturing is standardized that they are applicable to machines of different makes.

Delivery unit

1. Alternating current motor controlled delivery brake helps collect and align the paper.

2. You can also control each unit of the machine by using the 10.4’ touch screen at delivery unit.

3. Auxiliary delivery rack ensures non-stop delivery.