The adoption of automatic die cutting machines brings numerous operational advantages for businesses. These machines improve the overall efficiency of production by facilitating faster processing times and reducing material waste through precise cutting capabilities. Industries benefit from a notable increase in productivity as these systems allow for high-volume tasks to be completed without compromising the quality of outputs.

The versatility of automatic die cutting machines means they can handle a range of materials, further enhancing their application across sectors such as packaging, textiles, and automotive. Ultimately, implementing this technology can lead to substantial cost savings while ensuring high standards in manufacturing processes.

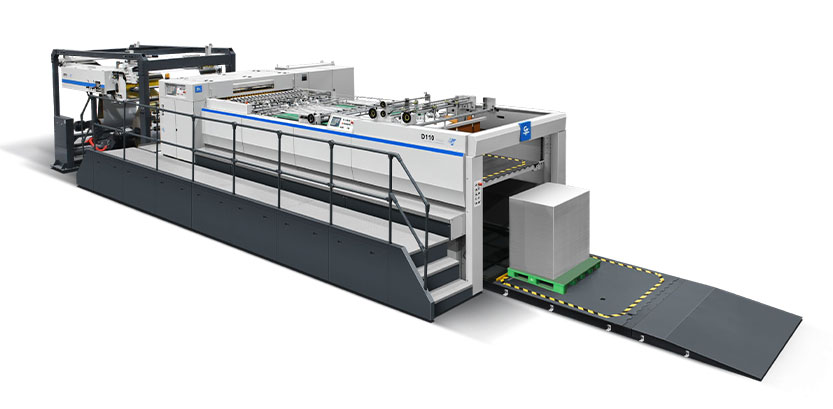

Understanding the Basics of Automatic Die Cutting Machines

An automatic die cutting machine is designed to streamline the cutting process across various materials with impressive efficiency and precision. These machines utilize advanced technology to create intricate shapes and designs, which are crucial for industries like packaging, textiles, and automotive.

The integration of automation enhances speed while reducing manual labor, allowing businesses to meet higher production demands. Users benefit from consistent cut quality, which leads to better product outcomes. Understanding its fundamental operation is key for industries looking to optimize their material processing capabilities effectively. The flexibility of these machines enables adaptation across diverse applications, resulting in significant productivity improvements.

Key Applications of Automatic Die Cutting Machines in Industries

Automatic die cutting machines play a pivotal role across several industries, from packaging to textiles, and even electronics.

1. In the packaging sector, these machines ensure consistent and precise cuts for boxes, labels, and protective coverings.

2. The automotive industry benefits from die cutting by producing intricate components with high accuracy for interior and exterior parts.

3. The textile industry utilizes these machines for cutting fabrics in fashion and upholstery, significantly reducing waste and enhancing productivity.

Table 1 below outlines some primary applications across various sectors:

|

Industry |

Application |

Benefits |

|

Packaging |

Box formation, labels |

Increased speed, uniformity |

|

Automotive |

Interior/exterior parts |

High precision, reduced errors |

|

Textile |

Fabric cutting |

Lower waste, enhanced efficiency |

|

Electronics |

Circuit board components |

Precision cuts for complex shapes |

By automating the die cutting process, industries can streamline operations while maintaining high standards of quality. This aspect not only aids in meeting production demands but also supports sustainable practices by minimizing material wastage. As industries continue to adopt advanced technologies, the relevance of automatic die cutting machines is set to grow further.

Enhancing Efficiency and Precision with Die Cutting Technology

Automatic die cutting machines are designed to enhance both efficiency and precision in various cutting processes. By employing advanced technology, these machines can handle complex designs with a level of accuracy that manual methods often struggle to achieve. The ability to program specific cutting patterns not only reduces material waste but also ensures consistent results across large production runs.

Moreover, the speed at which these machines operate allows businesses to increase their output without compromising on quality, ultimately leading to significant productivity benefits. As industries continue to adopt this technology, the impact on operational efficiency becomes increasingly evident, positioning automatic die cutting as a cornerstone of modern manufacturing processes.

Exploring the Benefits of Automatic Die Cutting Machines for Productivity

Automatic die cutting machines significantly improve productivity by streamlining production processes and reducing labor costs. These machines can handle large volumes of materials with exceptional speed and consistency, minimizing downtime during operations. As a result, manufacturers can meet tight deadlines while maintaining high-quality standards.

“An efficient die cutting system can reduce the time required for setup and changeovers, allowing companies to respond quickly to market demands.”

Integrating automatic die cutting technology enables businesses to optimize their workflow, providing a seamless cutting experience across various materials. The precision of these machines ensures minimal waste, which not only conserves resources but also contributes to better overall yield. By utilizing automatic systems, organizations can focus on scaling their operations without sacrificing output quality or efficiency.

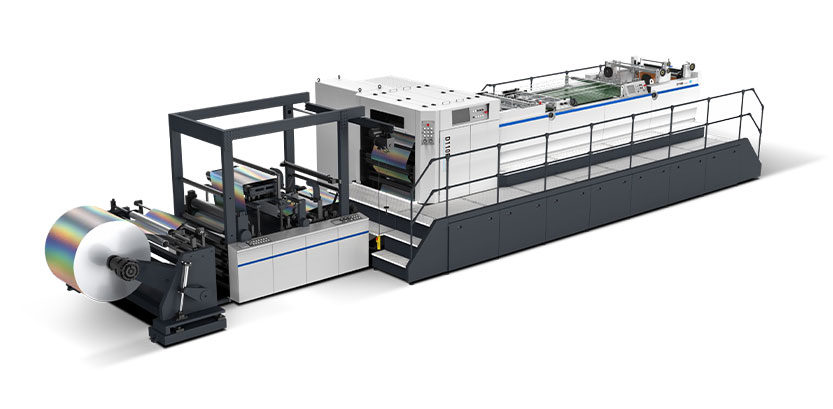

The Role of Automatic Die Cutting in Material Cutting Processes

Automatic die cutting machines streamline the material cutting process by employing advanced technology that ensures precision and efficiency.

1. Material Versatility: Processes paper, cardboard, and synthetic materials.

2. Automated Operation: Reduces manual intervention and improves consistency.

3. High-Speed Production: Maintains precision during rapid output cycles.

4. Waste Reduction: Optimizes material usage through accurate cutting.

5. Cost Efficiency: Balances productivity gains with operational savings.

Comparative Analysis: Manual vs. Automatic Die Cutting Systems

When comparing manual and automatic die cutting systems, notable differences in speed, accuracy, and operator involvement emerge.

Manual systems often rely heavily on human skill for precision and consistency, which can lead to variability in product quality. Operators must continually adjust techniques based on materials and workload, which can impede production rates.

In contrast, automatic die cutting machines are programmed for high-speed execution, minimizing human error and maintaining consistent precision across large volumes of cutting work. These machines effectively handle diverse materials, ensuring that intricate designs are produced with minimal waste.

As industries evolve, the advantages offered by automation make a compelling case for the shift away from manual processes

Evaluating Cost Savings through Automated Die Cutting Techniques

Automated die cutting techniques present significant cost savings for businesses by streamlining production processes. These machines reduce labor costs, as they require less manual oversight compared to traditional methods.

Additionally, the precision offered by automatic die cutting minimizes material waste, ensuring that resources are utilized effectively. This efficiency translates into lower overall production costs.

Automatic Die Cutting Machine the ability to produce high-quality cuts with minimal errors enhances product consistency, leading to improved customer satisfaction and reduced returns.

As industries seek to optimize their operations, integrating automated systems not only offsets initial investments but also fosters long-term financial benefits through increased productivity and reduced operational expenditure.

Conclusion

The advancements in automatic die cutting machines have led to significant improvements in the efficiency and precision of cutting processes across various industries. By automating the die cutting operation, businesses can streamline their workflows and effectively manage high production demands. These machines not only minimize material wastage but also enhance product quality through consistent and accurate cuts.

As industries continue to embrace automation, the role of automatic die cutting machines becomes increasingly vital for achieving productivity gains and maintaining competitive advantages.

Act now!

Contact our customer service team for free shopping guides and the latest product catalogs!