The manual crank machine is holding you back, errors are eating into your profits, and the market is moving faster than your production line. You’re searching for an automatic die cutting machine, but the sheer number of models, specs, and promises is overwhelming. You don’t need another list of generic features; you need a clear, expert-filtered map of what truly matters. Forget the sales jargon. Based on a decade of hands-on experience in packaging and print finishing, I’ll cut through the noise. The real answer lies not in any single spec, but in how five critical pillars—precision, power, adaptability, intelligence, and durability—come together in a system that fits your reality. Let’s get into it.

Uncompromising Precision and Alignment

Let's set aside speed for a moment. If a machine can't cut where it should, all other features are just a waste of electricity. Precision is the soul of a professional automated cutting system.

-

The Myth of ‘Good Enough’: In some factories, operators constantly adjust the die, wasting 30 minutes per job setup. That’s not production; that’s artisanal struggle. You need repeatable accuracy, often measured in fractions of a millimeter. Look for specifications like ±0.1mm or better registration accuracy. This isn’t just a number; it’s what allows you to run a 10,000-piece order overnight without a single misaligned kiss cut on your premium stickers.

-

The guidance system is crucial: Ask how the machine achieves this. High-end systems like those from Guowang often employ a combination of precision-ground servo drives and linear guides. Think of it as the difference between a bicycle chain and a high-performance timing belt—one has slack, the other has definitive, predictable movement.

-

Vision Systems: For complex print-to-cut applications, an optical registration system is non-negotiable. It uses cameras to read fiducial marks on your pre-printed material and auto-corrects the cutting path. My rule of thumb: if you’re doing anything with pre-printed graphics, this feature pays for itself by eliminating material waste and setup time alone.

Power and Versatility

Your machine isn’t cutting air; it’s confronting corrugated cardboard, delicate polyester film, adhesive foams, and everything in between. The machine’s tonnage and tooling adaptability determine its real-world usefulness.

-

Understanding Cutting Force: This isn’t ‘more is better.’ It’s ‘right is best.’ A 40-ton machine can crush through thick greyboard but might be overkill and harsh on a simple paperboard carton. A 20-ton machine might be perfect for folding cartons but fail on dense gasket materials. Consider your thickest, toughest substrate and add a 20-30% buffer for future needs. Guowang’s engineers often advise clients to run their actual materials in a demo, which is the only way to be sure.

-

Beyond the Steel Rule Die: The modern automatic die cutter is a multi-tool. Check compatibility with:

-

Laser-cut flexible dies: Faster setup, perfect for short runs.

-

Rounded-edge kiss-cutting tools: Essential for labels and stickers.

-

Creasing and perforation tools: For folding cartons.

-

Stripping and waste removal: Can the machine automatically strip the skeleton web? This is a massive labor saver.

-

-

The Throughput Engine: Speed vs. Productivity: Manufacturers love to advertise ‘cycles per hour.’ Be skeptical. True productivity is ‘sellable units per hour.’ A slower machine with faster job changeover and automated stripping will often beat a ‘fast’ machine that requires 45 minutes of manual setup and cleaning. Look at the overall workflow efficiency.

Software, Controls, and Ease of Use

This is where cheap machines reveal their true cost. A clunky, confusing control panel will cripple your operators and murder your efficiency.

-

Intuitive Interface is Key: The best control panels are like a modern smartphone—logical, responsive, and graphical. Touchscreens with job storage, recipe saving (pressure, speed for Material X), and clear diagnostics are essential. I’ve seen brilliant operators reduced to frustration by a poorly translated 90s-era button panel. Haptic feedback and clear visual workflows matter.

-

Software Connectivity: In an Industry 4.0 world, your die cutter shouldn’t be an island. Can it import cutting layouts directly from your design software (like .DXF or .AI files)? Does it offer job tracking and predictive maintenance alerts? This data is gold for managing your shop floor.

-

Safety as a Feature: Interlocked guards, light curtains, and emergency stops aren’t just compliance—they’re peace of mind. A well-designed safety system also allows for faster, safer access for cleaning and tool changes, indirectly boosting uptime.

Reliable Engineering and Support

A die cutter is a marathon runner, not a sprinter. You’re investing in a 10+ year asset. Its construction and the support behind it are critical.

-

Frame and Construction: Look for a rigid, stress-relieved frame (often one-piece cast or heavy welded steel). This mass absorbs vibration, which is the enemy of precision and component longevity. Open the panels—are the internal components neatly laid out and robust, or a mess of wires and thin metal?

-

The Service Lifeline: Here’s my strongest opinion: the best machine is useless without stellar support. Before buying, investigate:

-

Is there a local, trained technician?

-

What is the average response time for a breakdown?

-

Are common spare parts in stock locally?

A brand like Guowang builds its reputation not just on machine reliability, but on a responsive global support network that understands that downtime means lost money.

-

-

Total Cost of Ownership: Look beyond the price tag. Factor in energy consumption (servo motors are often more efficient), typical spare part costs, and required maintenance intervals. A slightly more expensive machine with lower running costs is almost always the smarter financial choice.

The advantages of customization and scalability

Your operation is unique. The best suppliers don’t just sell a box; they provide a solution.

-

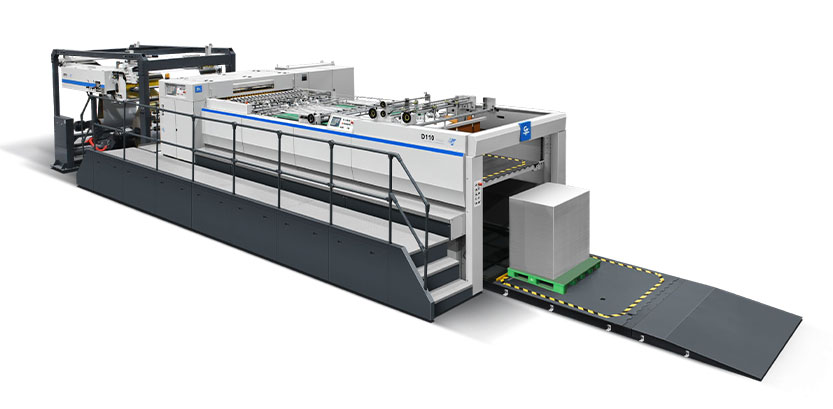

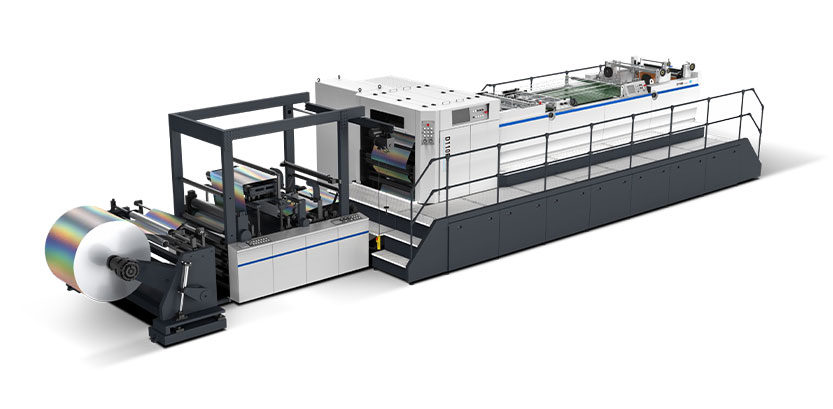

Modular Add-Ons: Can you start with a core flatbed die cutter and later add an automatic sheet feeder, a pallet unloader, or a finished-product stacking system? This scalability protects your investment.

-

True Partnership: Does the salesperson ask deep questions about your workflow, bottleneck materials, and future goals? Or just quote a price? The right partner will sometimes even advise against a more expensive feature you don’t need—that’s a sign of trust.

-

The Human Touch in a Digital Age: Finally, trust your gut during the demo. How do the engineers interact with the machine? Is the setup logical? Does the company offer comprehensive, hands-on training for your team, not just a manual? This human layer of knowledge transfer is what turns a new machine from a scary liability into a productive team member.

Conclusion

Stop researching and start experiencing. The theory only gets you so far. The true test of an automatic die cutting machine is how it handles your materials, your designs, and fits into your team’s rhythm.We invite you to move from a generic buyer’s guide to a personalized solution. Contact the Guowang team today to schedule a no-obligation, live material test. Bring your toughest stock, your most complex cut file, and your biggest production challenge. Let us demonstrate how a Guowang automated die cutting system, engineered around these core principles, can transform your productivity and precision. Visit our [Contact Page for a Custom Demo] to start the conversation.

This article was crafted with insights from industry veterans and real-world shop floor experience. While AI-assisted tools were used for initial research and grammar checking, the perspectives, analysis, and conclusions are uniquely human, born from years of troubleshooting, optimizing, and witnessing the evolution of die-cutting technology firsthand.