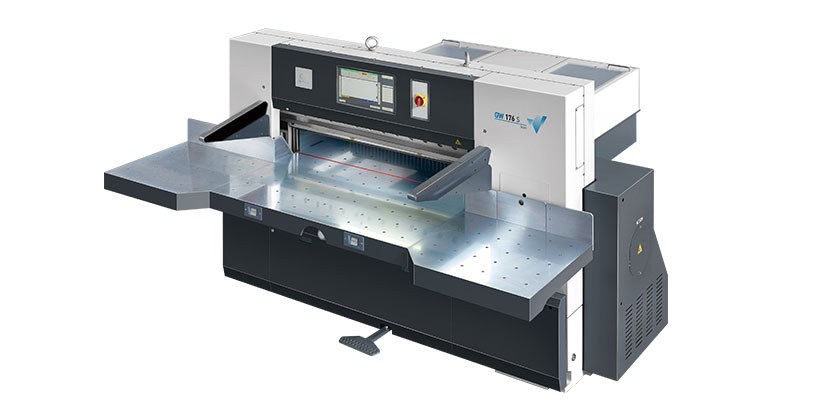

Installation parameters

| Category |

1760(Twin Turbine) |

| Machine length |

3870mm |

| Machine width |

3760mm |

| Machine height |

1730mm |

| Machine foundation length |

3000mm |

| Machine foundation width |

3300mm |

| Machine foundation thickness |

250mm |

| Machine half width |

1540mm |

| Net weight |

6200kg |

| Packing size |

3700*1600*2300mm |

Technical parameters

| Category |

1760(Twin Turbine) |

| Maximum cutting length |

2000mm |

| Maximum cutting width |

1760mm |

| Maximum cutting height (excluding pressure plate) |

165mm |

| Minimum cutting |

With pressure plate: 120mm

Without pressure plate: 35mm |

| Length in front of cutting point table |

750mm |

| Length behind cutting point table |

2620mm |

| Auxiliary platform length (optional) |

1000mm |

| Auxiliary platform width (optional) |

1000mm |

| Desktop height |

900mm |

| Pressing plate pressure |

Min: 300daN

Max: 7000daN |

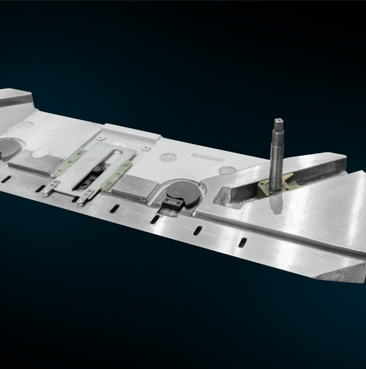

Blade specification

(thickness*width*length) |

13.75*160*2000mm |

| Maximum sharpening point |

60mm |

| Cutting speed |

45 times/min |

| Paper feeding speed (maximum) |

48 meters/min |

| Main power |

7.5kw |

| Power supply voltage |

380v |

| Wire thickness |

4mm² |

Main performance

1. The high-precision and high-rigidity frame-type paper feeding mechanism is equipped with linear guides and high-precision gapless ball screws to ensure paper feeding accuracy.

2. The display screen uses products from Taiwan's LCD screen manufacturer AU, which ensures its service life.

3. The computer part is a Taiwan industrial computer, which has reliable performance and stability, and can realize multi-machine communication and remote computer management.

4. The computer operation screen adopts a humanized design, making it easy for operators to operate.

5. The paper feeding motor adopts Japan's Yaskawa servo motor to achieve high-precision and fast positioning.

6. The computer control part is powered by Mean Well (MW) switching power supply, which ensures the stability of the power supply, effectively protects the computer control part, and avoids damage to the computer control part caused by excessive power supply.

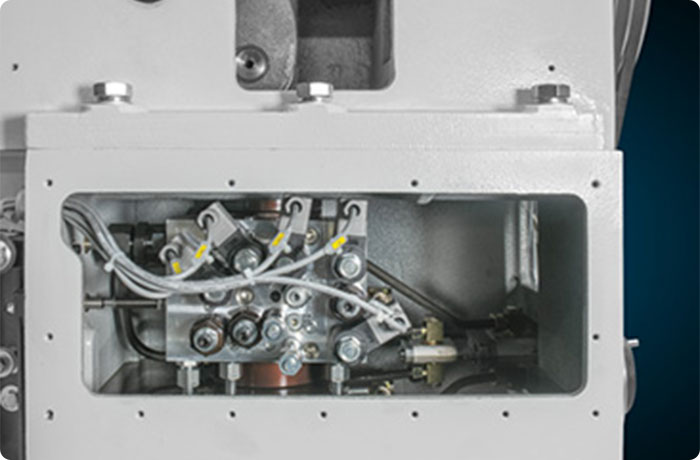

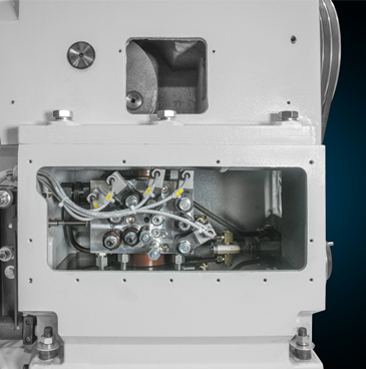

7. The main low-voltage control parts of the whole machine all use imported electrical appliances, including OMRON, IDEC, Schneider, American EATON, etc.

8. The hydraulic part adopts a fast pressurization system, the pressure meets the German TUV safety certification, and uses an American proportional valve to achieve stepless pressure adjustment through a 19-inch touch screen.

9. The whole machine adopts a gantry structure, which is convenient for users to install and adjust.

10. The frame adopts the internationally popular split structure, which effectively improves the cutting accuracy of the machine and facilitates the maintenance work of users.

11. The chrome-plated working platform saves users' maintenance time and extends its service life.

12. The working platform is also equipped with a blowing structure to facilitate paper pushing and feeding.

13. The built-in knife back insurance structure and 10 sets of highly reliable light and shadow grating protection ensure the personal safety of the operator.

14. The uniquely designed knife back insurance structure avoids damage to the machine caused by misoperation.

15. All large parts of the whole machine have been treated with aging vibration and will not deform after long-term use.

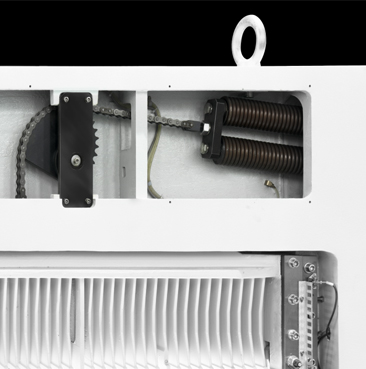

16. The efficient double worm gear transmission structure greatly improves the work efficiency, so that the number of cutting times can reach 45 times/minute.

17. The hook-type knife installation structure makes the knife change simple and easy.

18. The cutting part is equipped with an automatic lubrication system as standard to increase work efficiency and extend the service life of the equipment.

19. The paper press adopts a double spring structure to ensure the safety of the operator.