With advancements in precision control and automation technology, manufacturers can produce stunning decorative effects that offer superior aesthetic appeal while reducing material waste. Key features such as digital temperature control, automatic foil feeding systems, and precision pressure mechanisms collectively contribute to optimal production efficiency and consistent quality.

Moreover, the real-world applications of high-performance foil stamping machine illustrate their importance across various industries, from luxury packaging to security printing.

Understanding the Functionality and Benefits of Foil Stamping Machine

Foil stamping machine offer four key benefits:

1. Premium Decorative Effects: Create luxurious metallic, holographic, and pigmented finishes that enhance product value

2. Precision Processing: Achieve micron-level accuracy in complex pattern reproduction

3. High Efficiency Production: Automated systems enable rapid mass production with consistent quality

4. Multi-material Adaptability: Process various materials including paper, plastic, leather, and fabrics

Innovations in foil stamping technology, such as UV curing systems and holographic transfer effects, have further expanded the functional applications of foil stamping in modern manufacturing.

Innovative Production Techniques in Foil Stamping Technology

Recent advancements in foil stamping technology have led to more precise, efficient, and environmentally friendly production processes.

1. CNC Precision Control: Digital systems enable micrometer-level positioning accuracy

2. Intelligent Temperature Management: PID temperature control ensures consistent heating performance

3. Eco-friendly Foil Materials: Development of recyclable and biodegradable foil materials

4. Hybrid Processing Technology: Integration of stamping, embossing, and printing in one operation

These innovations not only improve production efficiency but also support sustainable manufacturing practices while expanding creative possibilities.

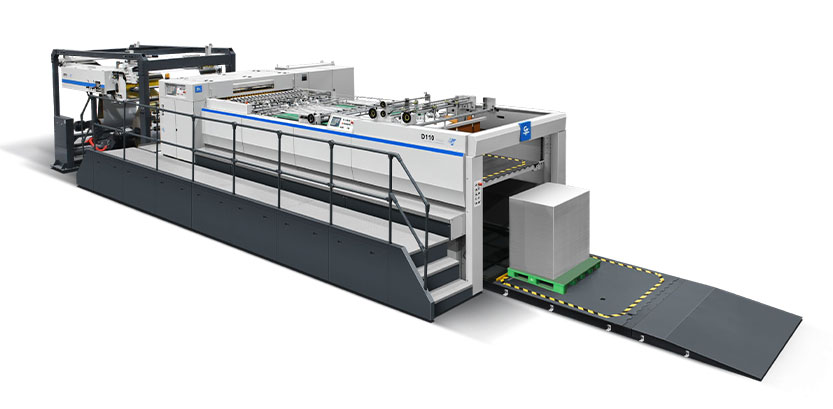

Key Components Driving Efficiency in Foil Stamping Machine

The efficiency and performance of foil stamping machine depend on several key components.

1. Heating System: Precision temperature control ensures optimal foil transfer quality

2. Pressure Mechanism: Hydraulic or pneumatic systems provide consistent stamping pressure

3. Foil Feeding System: Automatic foil advancement and tension control reduce waste

4. Positioning System: High-precision guides and slides ensure accurate pattern alignment

5. Control System: PLC and touchscreen interfaces enable precise parameter adjustment

Together, these components create a production system that delivers both high efficiency and exceptional quality consistency.

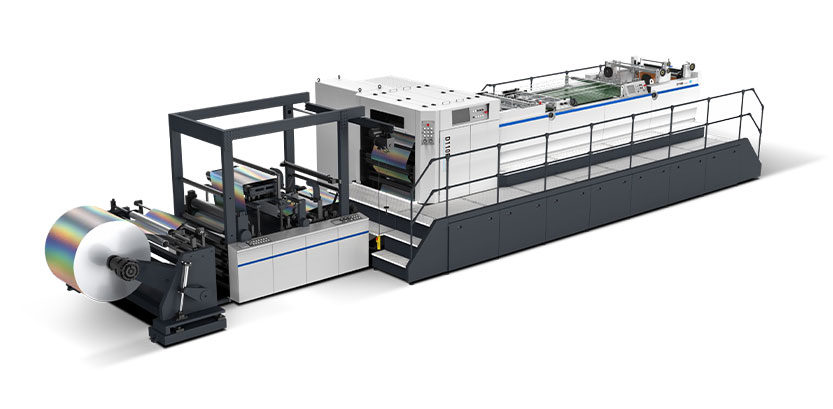

Real-World Applications: Optimizing Foil Stamping Processes

Foil stamping machine are designed to meet the demands of various industrial applications and product requirements. For example, in luxury packaging production, high-precision machines can create sophisticated anti-counterfeiting features and premium decorative effects. In book binding and publication, foil stamping adds value and aesthetic appeal to cover designs. The security printing industry utilizes special foil stamping technology to produce documents such as certificates and passports with complex security features.

By adjusting parameters such as temperature, pressure, and stamping speed according to specific material characteristics and design requirements, manufacturers can optimize both production efficiency and final product quality for diverse application needs.

Conclusion

Foil stamping machine represent a perfect combination of traditional craftsmanship and modern technology. As manufacturing technologies continue to advance, we can expect further improvements in processing precision, production efficiency, environmental performance, and operational convenience.

Whether for luxury product packaging, security printing, or commercial promotion, investing in advanced foil stamping technology is an investment in product value enhancement and brand building. By staying informed about the latest technological developments and market trends, manufacturers can choose foil stamping solutions that not only improve production efficiency but also create greater commercial value.

Take Action Now!

Contact our team of expert consultants today for industry solutions and detailed product information! Let us help you find the perfect foil stamping solution for your production needs.