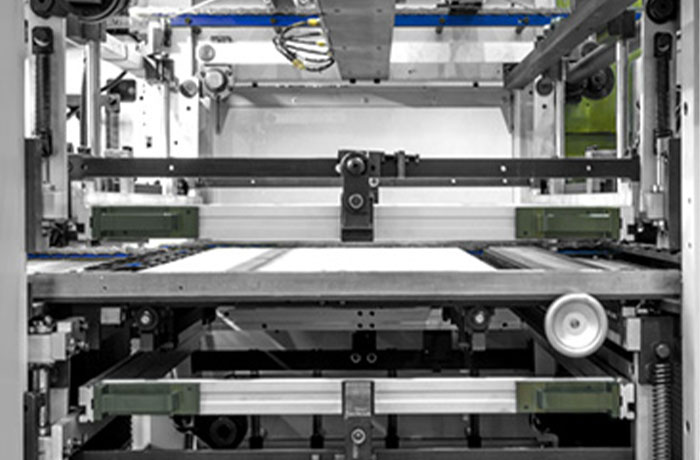

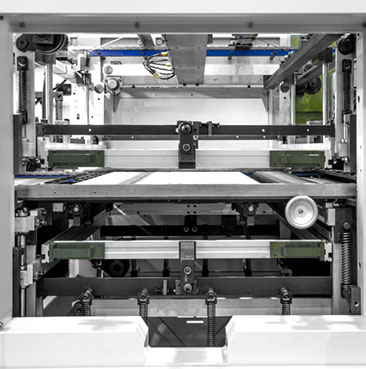

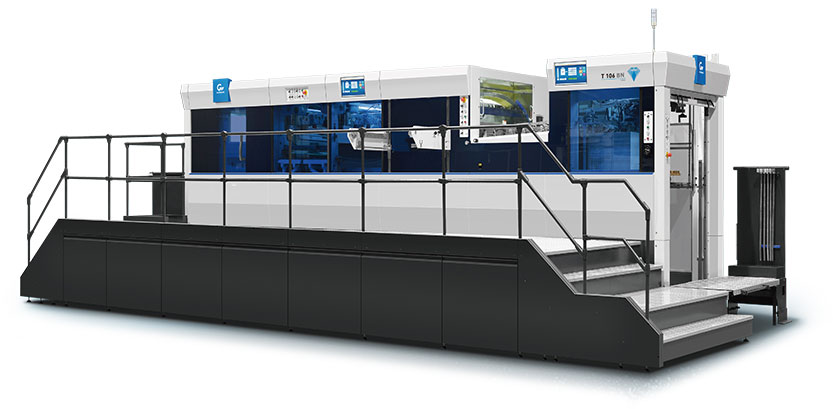

Die-cutting and waste stripping in one go: high-quality stacking and counting batches can be generated immediately, significantly reducing workload and related costs, complete paper collection, suitable for short-run non-repetitive orders.

Non-stop production: less setup and changeover time, thereby increasing production, intelligent paper feeder and unique die-cutting to printing registration, greatly reducing feed-related downtime.

Die-cutting and waste stripping conversion: one machine for multiple uses, capable of flexible conversion between die-cutting and waste stripping.

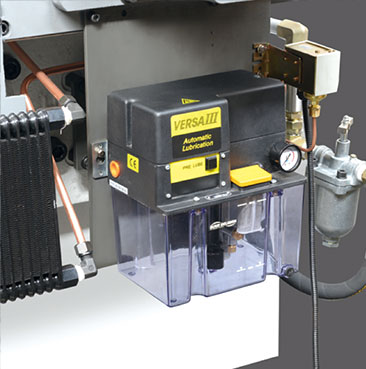

Time-saving ergonomics: fast conversion from die-cutting to waste stripping, efficient production data management.

Humanized operation interface: the hot stamping part adopts a 19-inch high-definition touch screen, all settings and functions can be easily realized by touch. Based on the special understanding of the equipment, a unique operation and control system has been developed, which is simple, intuitive and easy to operate.