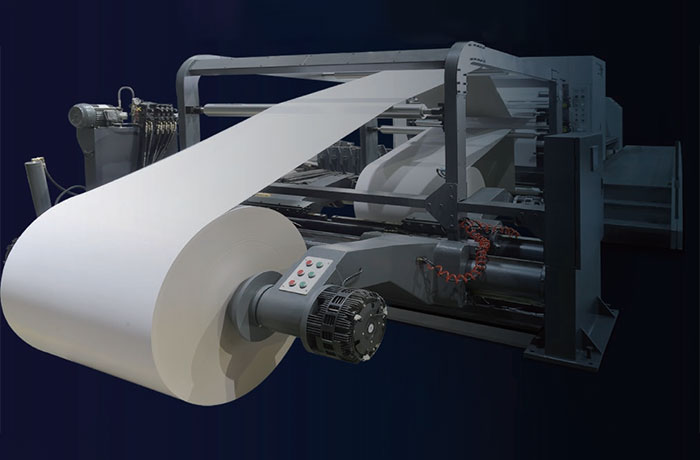

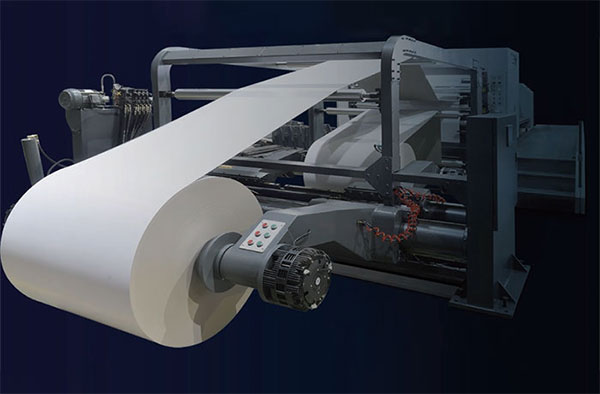

S190 Servo driven precision sheerer applise advanced technol-ogy from england and servo system for control. with rich experience and leading manufacturing technique of senior engineers, it is a new generation machine of high accuracy and efficiency which is widely used in paper mill, printing and packaging in dustry for cutting cardboard, coated paper, kraft paper, photo paper, alumimum foil paper, packing paper etc.

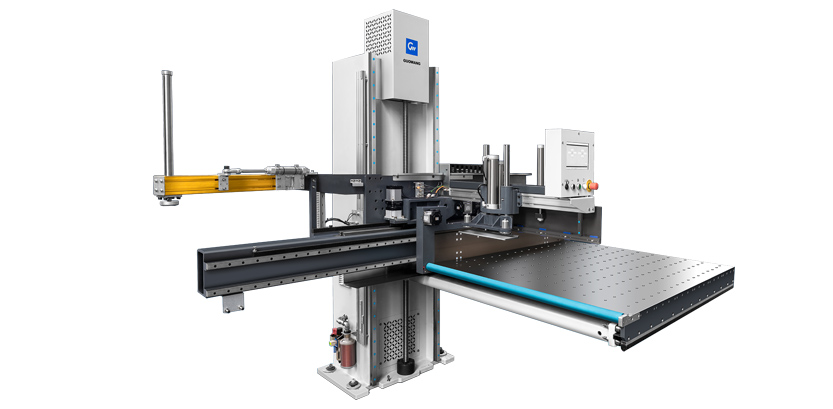

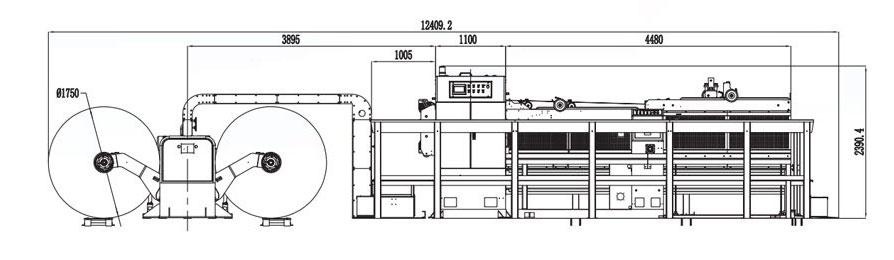

S-190 Installation Floor Plan

Specifications

| Model | S190 | |

| Cutting type | Top rotary knife,bottom fixed knife | |

| Paper weight range | gsm | 60-550 |

| Maximum paper format | mm | 1900 |

| Maximum web diameter | mm | 1800 |

| Cut-off length range | mm | 400-1650 |

| Cutting accuracy | mm | ±0.3 |

| Maximum cutting speed | m/min | 300 |

| Maximum number of cutting knives | p/min | 350 |

| Delivery height(incl. pallet) | mm | Including tray 1500 |

| main motor power | kw | 11 |

| Total power | kw | 30 |

| Gross weight | kg | 15000 |

| Air source | bar | 6-8 |

S Series Standard Configuration

| Shaftless pivotingarm unwind stand |

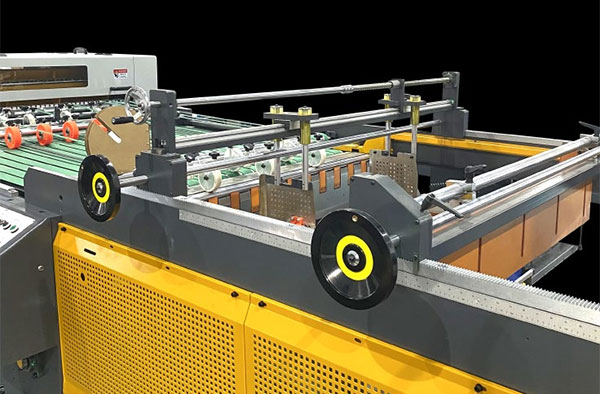

| High precision single rotarysheet cutter |

| Squareness Adjustment System |

| Static EliminatorDevice |

| Paper ConveyerSystem |

| Auto countingand Label inserter |

| Deliveryand AutoJogger System |

| Motorized de-curer |

| Auto-tension control |

| Main body steel structure |

Options

| Servo system for automatic slitter adjustment (ony forD series) | Non-stop automaticlogistics system |

| Rubber roller de-curler (OnyforD/Eseries) | Ink-jet device |

| Vacuum suction on paperedge | Enlarged hydraulic cylinderfor paperunwinder |

| Italy RE pneumatic brake forauto tension control | Dust suction forslitter |

| Cut-to-register | Shredder blower fortrimmingwaste |

| Customized mechanical chuckoruniversal conical chuck | Dust removal aftercutting |

| Non-stop automatic paper splicer | Blowerand beltsto assist deliveryof thin paper |

| Non-stop delivery | Cuttinglength to 2m |

| Automatic pallet feeding | Swing cylinder foroutofround paperroll |

| Middle slitting and waste edge collecting system (onlyforSseries) | Safety relay for 2-channel redundant control |

| Auto-EPC(Edge paper controD (onlyforSseries) | More options to select according to definite demands... |