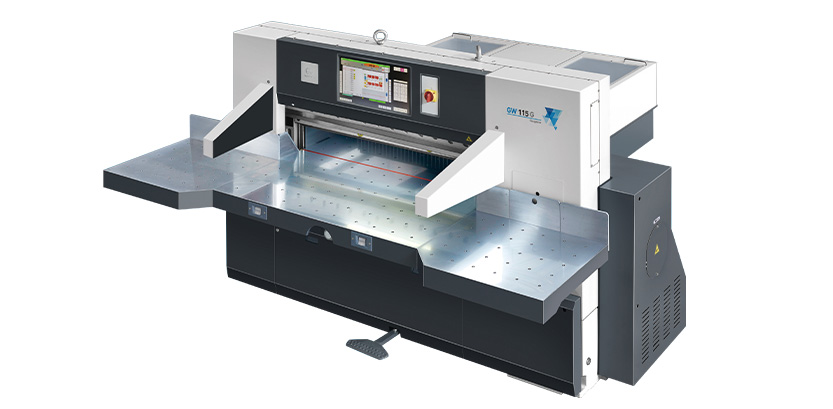

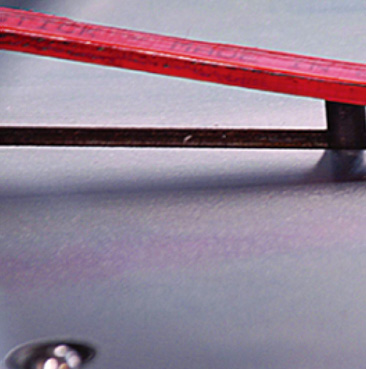

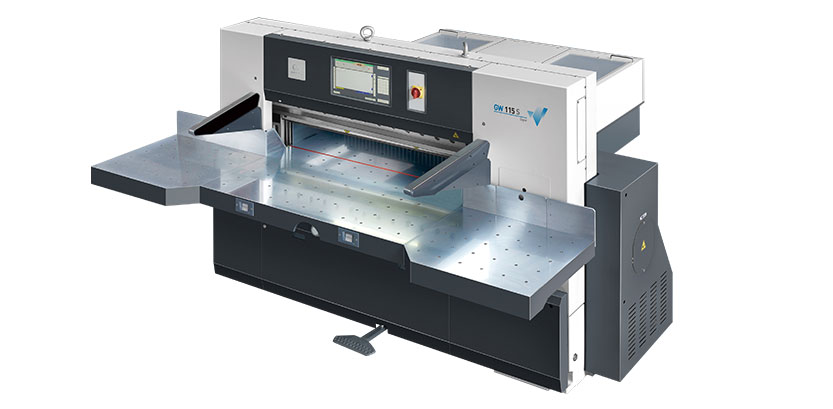

High-precision paper feeding structure: high-precision, high-rigidity frame-type paper feeding mechanism, equipped with linear guide rails and high-precision gapless ball screw, ensures paper feeding accuracy.

Reasonable structure: The frame adopts the internationally popular split structure, which effectively improves the cutting accuracy of the machine and facilitates user maintenance.

Reliable electrical appliances: The main low-voltage control parts of the whole machine are all imported electrical appliances, including OMRON, Panasonic, Schneider, EATON, etc.

Efficient cutting: The efficient double worm gear transmission structure greatly improves work efficiency, so that the cutting frequency can reach 45 times/minute.

Humanized operation interface: The hot stamping part adopts a 21.5-inch high-definition touch screen, and all settings and functions can be easily realized by touch. Based on the special understanding of the equipment, a unique operation and control system has been developed, which is simple, intuitive and easy to operate.